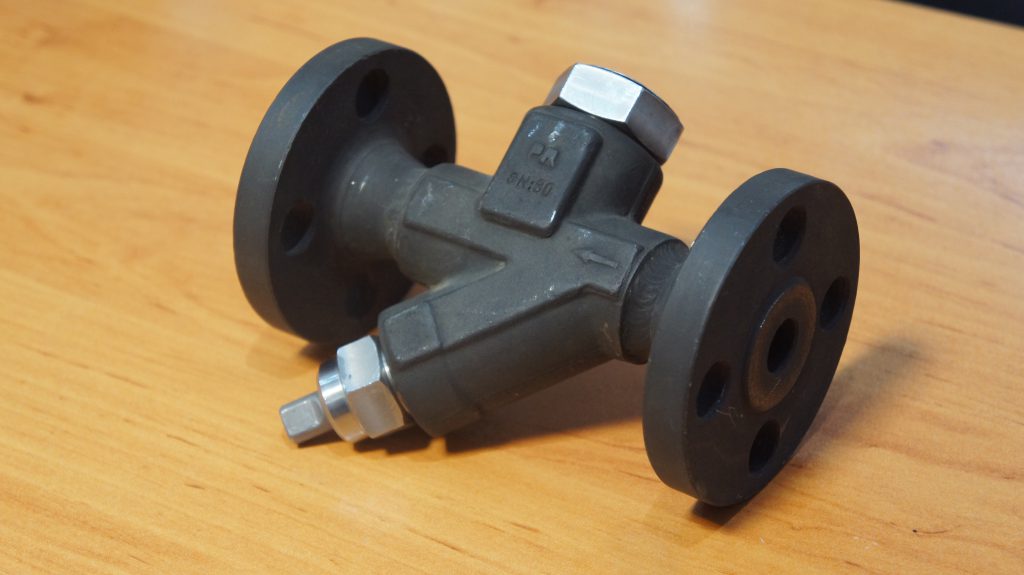

Traditional Thermodynamic steam trap

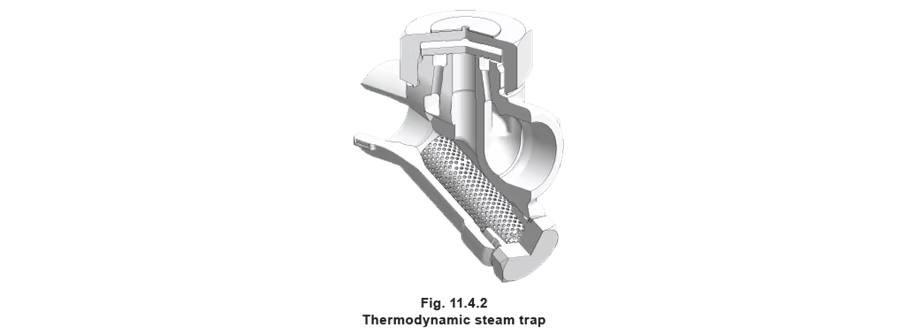

The thermodynamic trap is an extremely robust steam trap with a simple mode of operation. The trap operates by means of the dynamic effect of flash steam as it passes through the trap, as depicted in Figure 11.4.1. The only moving part is the disc above the flat face inside the control chamber or cap.

On start-up, incoming pressure raises the disc, and cool condensate plus air is immediately discharged from the inner ring, under the disc, and out through three peripheral outlets (only 2 shown, Figure 11.4.1, i).

Hot condensate flowing through the inlet passage into the chamber under the disc drops in pressure and releases flash steam moving at high velocity. This high velocity creates a low pressure area under the disc, drawing it towards its seat (Figure 11.4.1, ii).

At the same time, the flash steam pressure builds up inside the chamber above the disc, forcing it down against the incoming condensate until it seats on the inner and outer rings. At this point, the flash steam is trapped in the upper chamber, and the pressure above the disc equals the pressure being applied to the underside of the disc from the inner ring. However, the top of the disc is subject to a greater force than the underside, as it has a greater surface area.

Eventually the trapped pressure in the upper chamber falls as the flash steam condenses. The disc is raised by the now higher condensate pressure and the cycle repeats (Figure 11.4.1, iv).

The rate of operation depends on steam temperature and ambient conditions. Most traps will stay closed for between 20 and 40 seconds. If the trap opens too frequently, due to a cold, wet, and windy location, the rate of opening can be slowed by simply fitting an insulating cover onto the top of the trap.

Advantages of the thermodynamic steam trap

- Thermodynamic traps can operate across their entire working range without any adjustment or change of internals.

- They are compact, simple, lightweight and have a large condensate capacity for their size.

- Thermodynamic traps can be used on high pressure and superheated steam and are not affected by water hammer or vibration. The all stainless steel construction offers a high degree of resistance to corrosive condensate.

- Thermodynamic traps are not damaged by freezing and are unlikely to freeze if installed with the disc in a vertical plane and discharging freely to atmosphere. However, operation in this position may result in wear of the disc edge.

- As the disc is the only moving part, maintenance can easily be carried out without removing the trap from the line.

- The audible ‘click’ which occurs as the trap opens and closes makes trap testing very straightforward.

Disadvantages of the thermodynamic steam trap

- Thermodynamic steam traps will not work positively on exceptionally low differential pressures, as the velocity of flow across the underside of the disc is insufficient for lower pressure to occur. They are subjected to a minimum inlet pressure (typically 0.25 bar g) but can withstand a maximum back pressure of 80% of the inlet pressure.

- Thermodynamic traps can discharge a large amount of air on ‘start-up’ if the inlet pressure builds up slowly. However, rapid pressure build-up will cause high velocity air to shut the trap in the same way as steam, and it will ‘air-bind’. In this case a separate thermostatic air vent can be fitted in parallel with the trap. Modern thermodynamic steam traps can have an inbuilt anti-air-binding disc which prevents air pressure building up on top of the disc and allows air to escape, (Figure 11.4.3).

- The discharge of the trap can be noisy, and this factor may prohibit the use of a thermodynamic trap in some locations, e.g., outside a hospital ward or operating theatre. If this is a problem, it can easily be fitted with a diffuser which reduces the discharge noise.

- Care should be taken not to oversize a thermodynamic trap as this can increase cycle times and induce wear. Mains drainage applications often only need to be fitted with low-capacity versions, providing proper consideration is given to siting the drain pockets correctly.

Features

- Designed to fail open.

- Designed for superheating steam.

- Unaffected by corrosive condensate, freezing and water hammer.

- In-line maintenance.

- Designed to response to load charges.

- Excellent air handling.

- Small lightweight design.

- Performance testing per ASME PTC-39.1, ISO 7841 and 7842.